Infrastructure

Extrusion

department

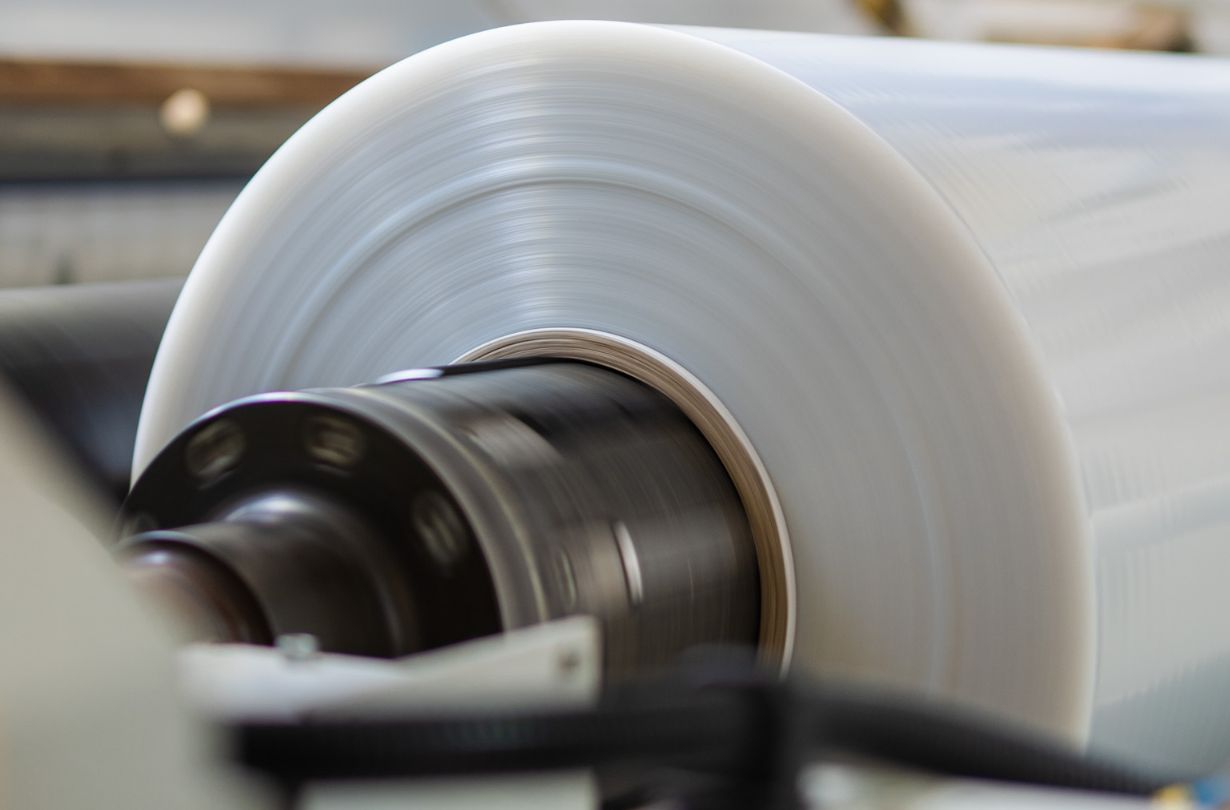

Our production consists of 4 co-extrusion lines designed by our technical office.

The entire production is equipped with self-control and diagnostic systems to maintain the production and quality parameters within well-defined tolerances. Due to the high speed of the lines, the feed of the granules is guaranteed and controlled by an automatic system, fed by a battery of 22 granule storage silos, with the possibility of storing up to 1500 tons of raw material.

Our production lines guarantee the high quality of the product and the high compliance with quality standards.

Thicknesses* between 22 µm and 300 µm.

*variable range based on the material to be made

Maximum reel width of 2800 mm

Maximum reel diameters of 1000 mm.

Extrusion

department

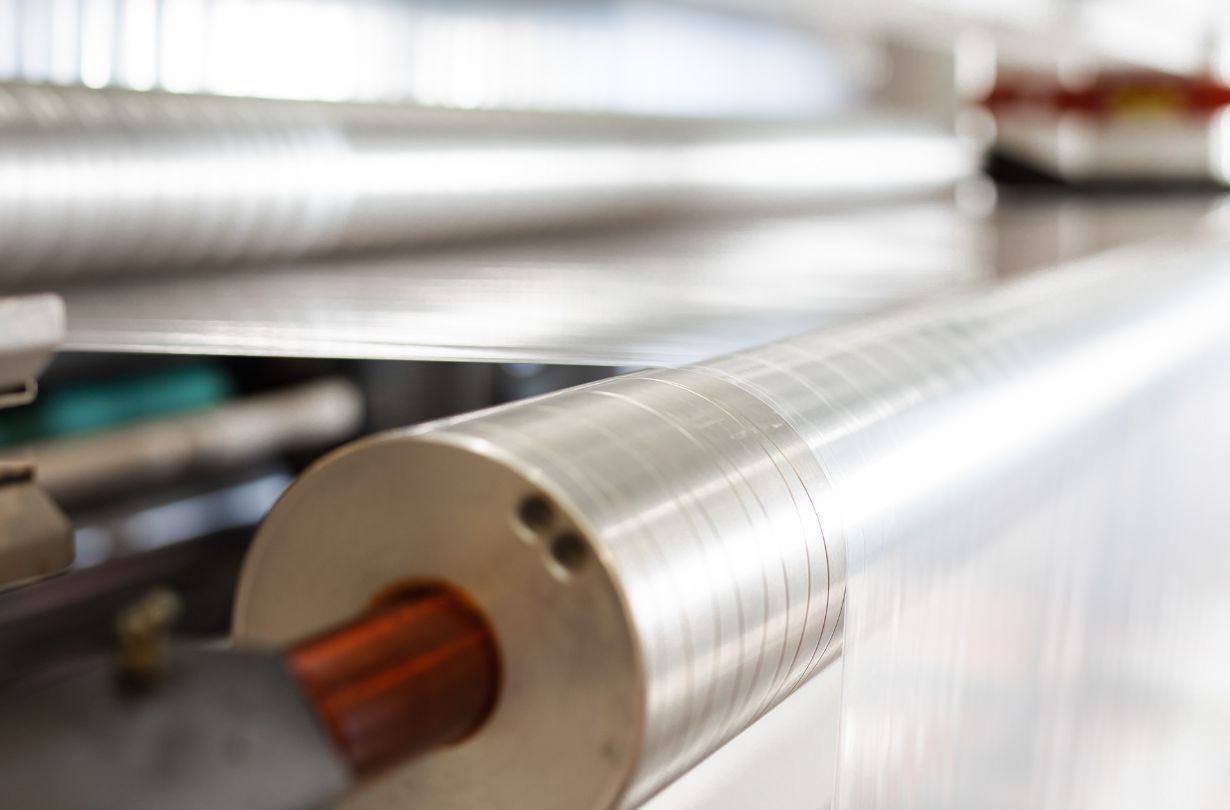

To complete the offer, there are inspection, cutting, winding (4 lines) and double-folding (1 line) services of the products made.

Starting from the mother reels, we are able to supply customized reels, satisfying every customer request.

We work constantly to increase the productivity and reliability of production plants, in order to be ready to face new challenges every day.

Cutting-edge technologies and the professionalism of the team ensure the correct performance of the activities, in compliance with the quality and safety standards set by our protocols.

Alberto Spadini

Plant Manager

Containment

chambers

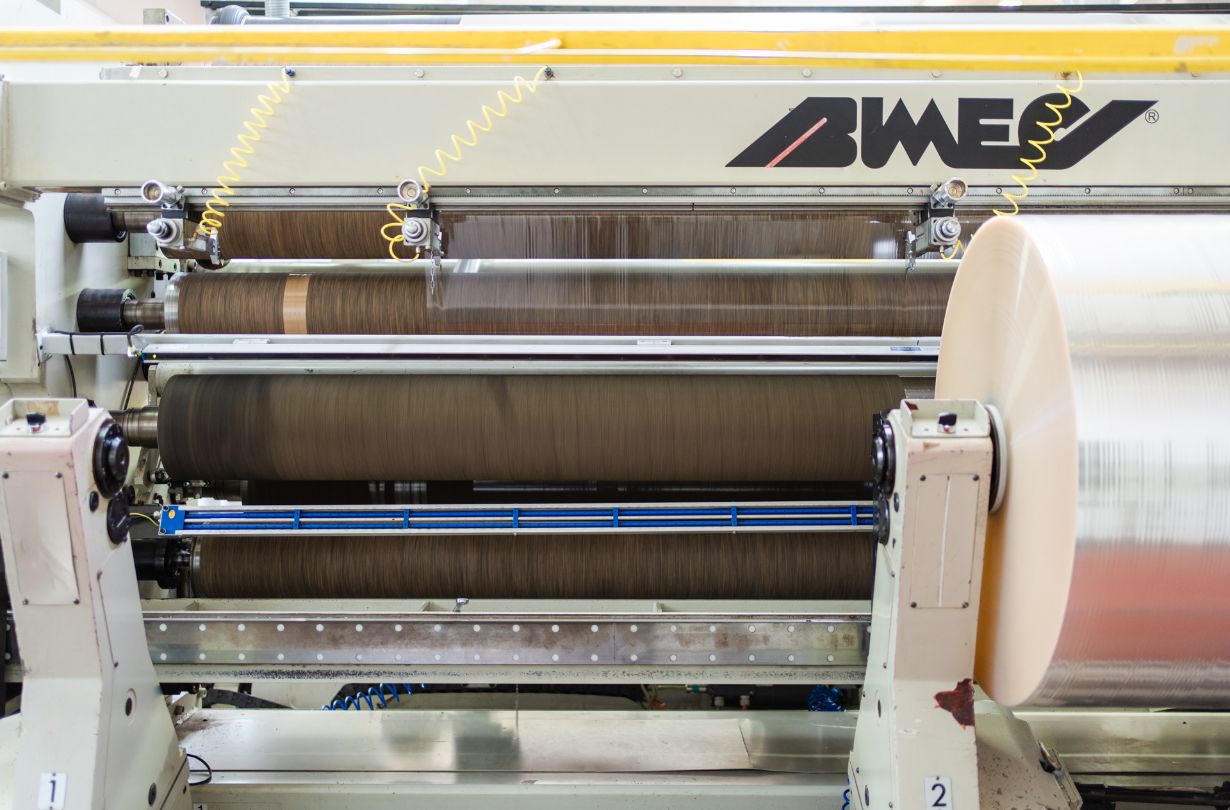

The process lines used in the production of films created for flexible food and/or sanitary packaging are installed in areas protected from potential environmental contaminants, such as dust or insects.

These factors, in the winding phase of the film on reels, are decisive for the quality of the product. Finely filtered air is introduced into the chambers and conditioned by 2 air handling units (UTA). This allows to maintain a stable and controlled climate, an optimal condition for the repeatability of the production processes.

The films produced are constantly checked using a dedicated system equipped with CCD cameras capable of detecting and classifying defects, such as infusions, pinpricks, insects, micro-holes, according to the established parameters

The checks are recorded for each reel produced and are used as a guide in subsequent internal processes or as a certification/history accompanying the reel, if it’s to be delivered.

Maturing

chambers

The CPP, or cast polypropylene, after the extrusion process requires a stabilization period, which in Verbano Film is normalized and speeded up inside our maturing chambers.

Without these chambers, the maturing phase would take several days, but thanks to them, the film is suitable for shipping in just 24 hours.